Story Time: When you win, you also lose

We won the business, but what did we bargain for?

This happened long ago, so I can actually tell the story without giving anything away. The Statue of Limitations has expired.

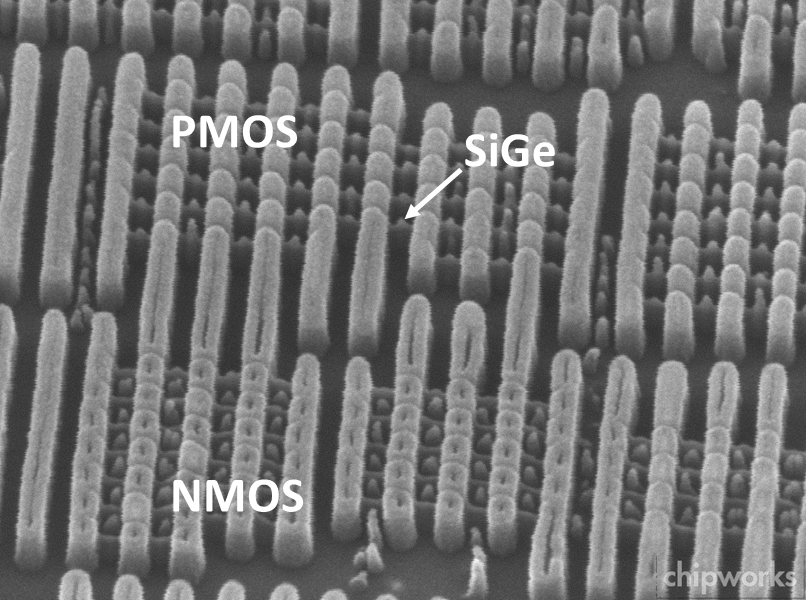

After I left the optical measuring microscope company, I joined a major semiconductor equipment maker, to do ostensibly the same thing: measure line-widths on photomasks, but instead of photons, we used electrons1. Of course, photomasks are interesting things. At the time, they were chrome patterns etched on glass, and while photons go right through the ULTE quartz of the mask, electrons, not so much. In fact, the major challenge with using an electron microscope to image the bits of chrome on glass is that the electrons charge up the chrome, and this sets up an electric field on the glass, and if you remember your basic physics, charged particles (aka Electrons) are impacted by this field build up.

We had some really cool technology to disperse the fields, to minimize the charging, and to give superior imaging performance, and thus to yield really good measurement performance. It was really groundbreaking.

I could go into the charge suppression technology, but that isn’t relevant for this conversation.

No, we had some ground breaking technology, we had demonstrated its performance, and we were winning orders.

But it was time to go to the big dog, the I company (Intel). At the time (late 1990’s) Intel had a captive mask shop2, that is they made their own photomasks, thus having ultimate control over a critical aspect of their ability to make chips.

I will admit that I was not ready for a selection exercise by Intel. The evaluation criteria was brutal. The amount of testing, validation, poring over the raw data, the haggling over specs like uptime, performance, and support.

It was intense. We were one of 4 vendors in the mix, and for about 3 months, we did little else but run the hamster wheel. I practically lived at their shop in Santa Clara. I became very close to two of their engineers, and their engineering lead.

We must have done full workups on probably 50 different masks.

Selection Day

As I mentioned, we were one of three vendors in the mix. We had done major amounts of work. We had done algorithm development to deliver the results the needed. We had committed to on site spares of critical components. We had done integration work to attach out instrument into their factory automation system.

But, we were on edge. We had shot our shot, my technical marketing engineer practically lived there, our engineering team committed to a roadmap for 18 months of improvements. Our VP/GM had wined and dined with their engineering lead (sadly, I was not invited).

How it went was that the selection team from Intel would visit all the vendors in person, and explain their decision. The day had come, and alas, we were the last on their list.

That is not a bad call. They deliver the bad news first, and us being last meant that we won the business.

Yay, we won intel.

Oh no…

At the time, there was a dichotomy. The good news is that you won the Intel business. But the bad news is that you won the Intel business.

Why?

Because they are (were) very demanding. They will make you better. Small details that you might be able to ignore from any other customer, you have to do. And it has to be your top priority. All other priorities go buh-bye.

Also, you can’t tell anybody you are working with them. Sure, in the industry, the scuttlebutt will be there, but you can’t use their name in marketing. You can’t have them on your “Customers List” PPT slide.

You get the pride of knowing that you won, and they will make you better. But boy is it an ass-kicker.

You won Intel. Woo hoo!

I left that job not long after that. The dot-com era was beginning to fade, and industry trends de-emphasized the photomask CD-SEM, and the writing was on the wall that they would be pulling all the engineering and development efforts from my line, refocusing it on the silicon products, and ultimately, they would exit the photomask business. I bolted at the opportunity to join another Silicon Valley icon.

Blast from the past

Not related, but I still get email from services that auction off equipment from wafer fabs that go belly up, and about 5 years ago, one of our old SEM’s was on the market for about $8K. An instrument that we sold new for $2.1M, on the used market for less than ten grand.

I do miss that time of my life.

One of the first meetings I had with the engineering team, I got major kudos because of my degree in physics, I was able to jawbone with them about the e-beam optics, and how Maxwell’s equations dictate the focal length and performance. ↩

I am not sure if they still do, but back then they made some of the best looking (and measuring) masks I had ever seen. As part of the contract, we got Intel to make a set of qualification masks for us, that were used to build, test, and calibrate new instruments. Their process control was (and probably still is) the creme de la creme.